Leather bags have always been a very important product category in the luggage industry. No matter how the market changes, leather bags with solid workmanship, reliable materials, and durability that can withstand long-term use always have a stable demand. That’s why when brands customize leather bags, they often place higher requirements on the professionalism of the manufacturing process.

So in this article, I will list the top ten custom leather bag manufacturers in China. If you are looking for similar manufacturers, please read this article. Whether you are a buyer or a store owner, this article hopes to be helpful to you!

Why choose China for Custom Leather Bag Manufacturing?

When you come to China, you will find that there are hundreds and thousands of manufacturers here. You don’t have to make a passive choice. Do you know? In China, it is no longer just about labor costs or simple production capacity; what matters more is its systematic ability in leather bag manufacturing.

The production of leather bags is essentially a highly coordinated set of processes rather than a single skill. From leather selection, cutting, and thinning to edge treatment, sewing control, hardware matching, structural reinforcement, and finally the final product inspection, each step directly affects the stability and consistency of the finished product. Not many countries can complete these processes within the same manufacturing system, and China is one of them.

In some key production areas of Guangdong, Zhejiang, and Hebei, leather bag factories are often located together with tanneries, hardware suppliers, zipper factories, packaging companies, and testing institutions. This highly concentrated industrial environment makes communication and adjustments very efficient. When design needs to be fine-tuned or there are problems with the materials, solutions are usually implemented in “day” increments rather than waiting for a long time.

Another major advantage of Chinese manufacturing lies in its ability to adapt to order sizes. Many factories can not only handle initial trial orders of several hundred pieces seriously, but also have the capacity to rapidly expand to tens of thousands of pieces once the product has been successfully verified. This flexibility becomes particularly important in 2026, as more and more brands choose to test the market first before cautiously increasing production.

At the raw material level, China also has significant advantages. Whether it is full-grain leather, top-grain leather, second-grain leather, recycled leather, or the increasingly popular bio-based alternative materials, they all have a stable supply. More importantly, mature manufacturers are well aware of the “temperament” of different materials in actual production. They understand the real reactions of leather to humidity, tension, edge oil, and usage period. These experiences often determine whether the products will be stable and controllable or encounter frequent problems after mass production.

What Qualities Define a Professional Custom Leather Bag Manufacturer?

Picking a reliable leather bag manufacturer isn’t about who has the fanciest website or the biggest factory. It’s about how they actually work, think, and solve problems. If you pay attention, a few clear signs will tell you whether a factory is worth your time.

1. Real Manufacturing Capability

A professional factory isn’t just talk—they can actually make what you’re asking for. That means having skilled workers, proper machinery, and production lines that can handle everything from small test orders to larger runs. You want a factory that can show you examples of similar projects and explain how they manage different bag types without losing quality.

2. Certifications and Compliance

Certifications matter because they show the factory follows international standards. Look for ISO, SGS, or other relevant quality and safety certificates. This is especially important if your bags need to meet export requirements. A factory that can’t provide proof of compliance is a risk you don’t want to take.

3. Samples That Tell the Truth

The way a factory handles samples says a lot. Professional manufacturers treat samples as a key step, not just a formality. They’ll test materials, patterns, and construction methods before you commit to bulk production. Good samples save you time, money, and headaches later.

4. Understanding Leather Inside and Out

Leather is tricky—it’s not like fabric. Top manufacturers know how different hides behave with tension, humidity, and over time. They understand cutting, stitching, edge finishing, and reinforcement. That knowledge is what keeps your bags looking great and holding up in real life.

5. Transparent Quality Control

You don’t want vague promises. A solid manufacturer can tell you exactly how they check quality: what gets inspected, when it happens, and what counts as a defect. Clear QC processes mean fewer surprises when your order arrives.

6. Communication That Actually Works

Problems happen, but a good factory communicates early and clearly. They explain what went wrong, why, and how they plan to fix it. Factories that avoid questions or give unclear answers are usually the ones that cause delays and frustration.

7. Flexibility and Scalability

Professional manufacturers can handle both small and large orders without compromising quality. They can adjust schedules, materials, and production methods to match your changing needs. This flexibility is key if you want to grow your collection or try new designs.

8. Long-Term Thinking

The best factories aren’t just thinking about your first order. They consider repeatability, material stability, and future scaling. They treat your brand as a partner, not just a one-time customer. That long-term perspective often makes the difference between a good product and a great one.

Top 10 Custom Leather Bag Manufacturers in China

| Rank | Manufacturer | Location | Years Experience | Monthly Capacity | MOQ | Key Specialties facebook+3 |

|---|---|---|---|---|---|---|

| 1 | Baijia Leather Products | Jiangmen/Guangzhou | 18+ | High-volume OEM | 10-50 pcs/style | Women’s cowhide totes, crossbody bags, woven designs, PU blends |

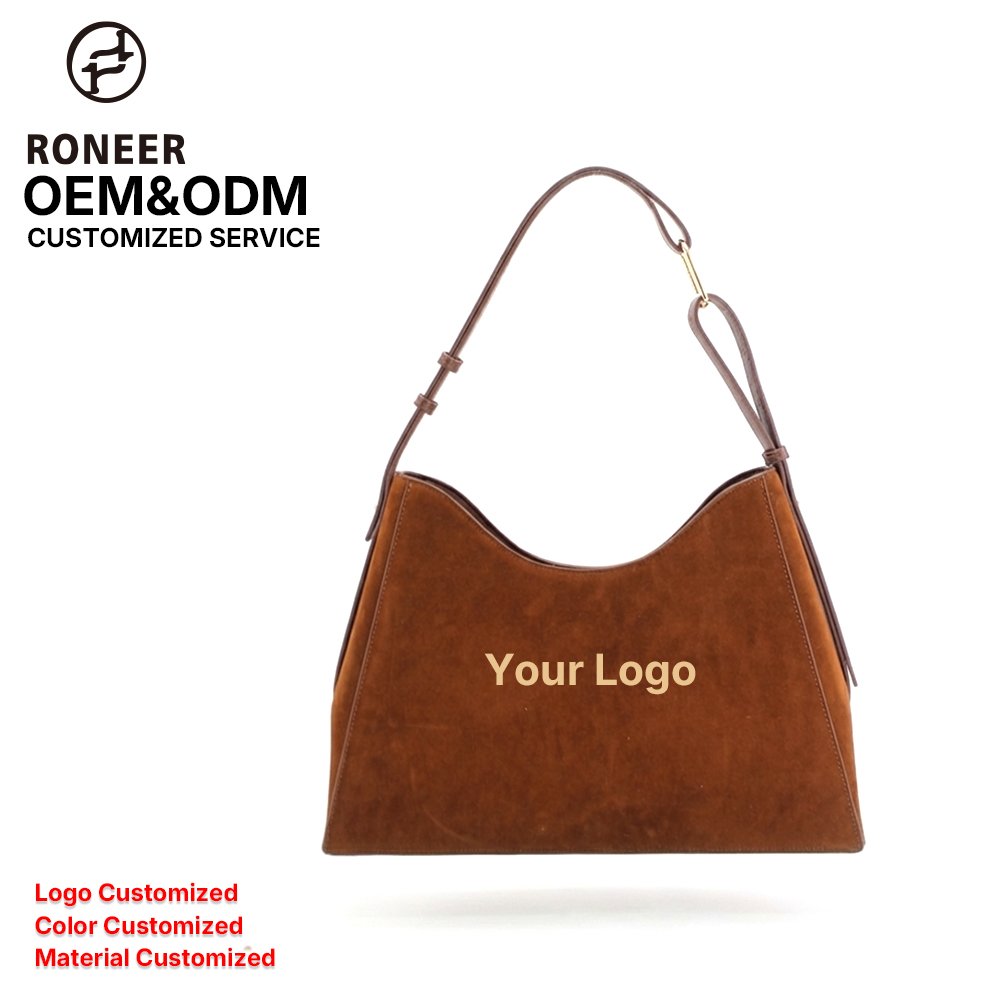

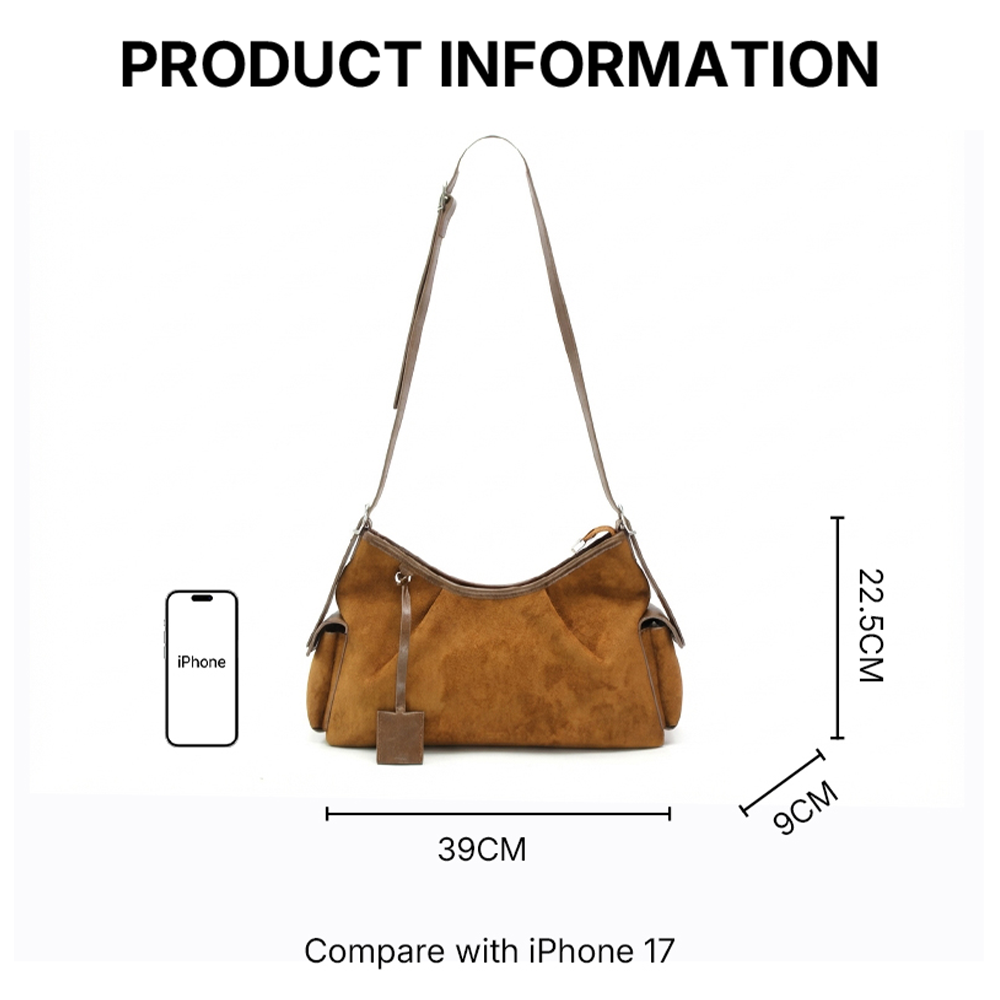

| 2 | RONEER Bags | Guangzhou | Established | Factory-direct | Flexible | Men’s messengers, women’s purses, handcrafted weaves |

| 3 | Gionar Leather | Guangzhou (Baiyun) | 19+ | 280,000 units | 50-200 pcs (genuine leather) | Luxury veg-tan totes, wallets, OEM/ODM luxury |

| 4 | B.S. Bag Factory | Guangzhou | Decades | Up to 80,000 pcs | Flexible (low for startups) | Leather/canvas handbags, OEM/ODM, eco-materials |

| 5 | Autron Industry | Guangzhou | Proven | 150,000 pcs | Negotiable | Structured quilted bags, CAD prototyping |

| 6 | Guangzhou Boshen Leather Goods | Guangzhou | 30+ | Large scale | 100+ | Veg-tan travel bags for luxury |

| 7 | Sitoy Group | Dongguan | 58 (since 1968) | 1M+ units | Scalable | Veg-tan travel bags for luxury |

| 8 | Sunteam | Guangzhou | Experienced | 100,000 pcs | Flexible | Ergonomic crossbodies, in-house tanning |

| 9 | Yongxin Leather Factory | Guangzhou | Established | 80-120k | Custom | Duffels, hand-stitched premium leather bags |

| 10 | Dongguan Topwin Leather | Dongguan | Proven | 60k | Boutique | Duffels, hand-stitched premium leather leather bags |

How to Choose the Right Custom Leather Bag Manufacturer in China?

Choosing the right manufacturer isn’t about finding the cheapest quote. It’s about reducing risk and making sure what you design can actually be produced, repeatedly and consistently. Here’s a practical way to approach it, step by step.

Step 1: Be Clear About What You Want to Make

Before contacting any factory, get clear on your own product. Know the bag type, target price range, materials, estimated quantity, and timeline. You don’t need every detail perfect, but the clearer you are, the more accurate the factory’s feedback will be.

Step 2: Shortlist Factories That Match Your Product Type

Not every factory is good at every bag. Some focus on soft leather totes, others on structured handbags or business bags. Look for manufacturers that already produce styles similar to yours. This saves time and avoids unnecessary trial and error.

Step 3: Pay Attention to the Questions They Ask

Good manufacturers don’t just quote and move on. They ask about usage, structure, weight, materials, and cost limits. These questions show they’re thinking about real production, not just winning an order.

Step 4: Evaluate the Sampling Process

Samples tell the real story. Check how the factory handles pattern making, material confirmation, and revisions. A serious approach to sampling usually means fewer problems during mass production.

Step 5: Inspect the Sample Like a Technician

Don’t judge the sample only by how it looks. Check stitching consistency, edge finishing, zipper alignment, and overall structure. Small flaws in samples often turn into big issues in bulk orders.

Step 6: Ask About Quality Control

A reliable factory can explain how quality is checked, at which stages inspections happen, and how defects are handled. If quality control sounds vague, that’s a warning sign.

Step 7: Confirm Communication and Response Style

Clear communication matters more than fast replies. You want a manufacturer that explains issues, gives options, and follows up properly. Good communication prevents misunderstandings later.

Step 8: Start With a Manageable Order

If possible, begin with a smaller order. This lets you test the factory’s consistency, delivery timing, and problem-solving ability before scaling up.

Step 9: Think Beyond the First Order

Ask yourself whether this factory can grow with you. Can they maintain quality over multiple runs? Can they handle higher volumes later? Long-term fit is more important than short-term convenience.

What Are the Key Trends in Custom Leather Bag Manufacturing for 2026?

By 2026, the trend of custom leather bags will no longer be solely based on the appearance design, but will be reflected in many practical aspects. The first is the material itself. Brands are increasingly focusing on the stability and origin of the leather, rather than simply pursuing a certain “soundly luxurious” type of leather. Whether it can be supplied in the long term and whether different batches are consistent have become more practical issues.

In terms of structure and craftsmanship, the design has become more rational. The market desires bags that are lighter, but they cannot sacrifice durability. This has led manufacturers to start focusing on aspects such as the shape, points of stress, and internal structure, rather than simply reducing the amount of materials used. Whether the edge finish is smooth, whether the stitching is straight, and whether the lining is clean – these seemingly minor details are now directly influencing the overall feel of the product.

The production methods are also changing. More and more brands are choosing to conduct small-scale market tests first, and then increase orders based on feedback. This requires factories to be more flexible in production scheduling, delivery times, and quality control, rather than solely focusing on large-scale production. Whether the quality can remain stable under changes in quantity is becoming an important capability.

Furthermore, communication methods are also changing. Brands no longer solely focus on price; instead, they are more willing to discuss with factories about processes, structures, and the possibility of long-term cooperation. Manufacturers who can clearly explain problems and provide practical suggestions will be more likely to gain trust. Overall, the manufacturing of custom leather bags in 2026 is returning to a more pragmatic, detail-oriented, and long-term value-oriented direction.

Conclusion

In China, the production of custom leather bags is no longer about finding the supplier with the lowest price. Instead, it involves establishing a production partnership, which can understand your product concept, respect your standards, and grow together with you.

If you approach procurement with a clear mindset, technical awareness, and realistic expectations, then by 2026 and beyond, China will remain one of the world’s most capable regions in transforming the concept of leather bags into reliable and scalable products.